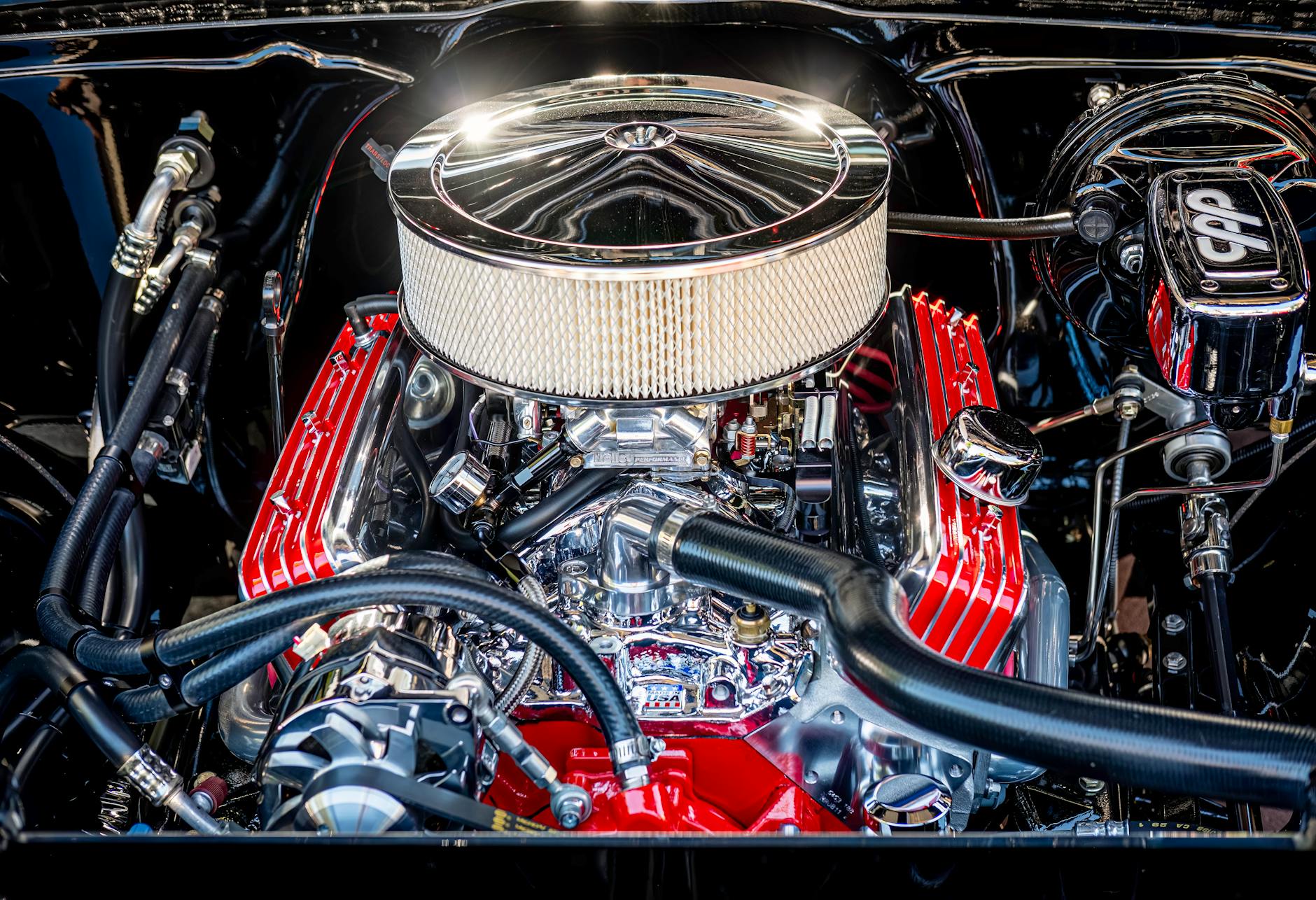

Are you dreaming of conquering rugged trails in your Jeep? That iconic 3.8L engine might hide nasty surprises that could turn your off-road adventures into expensive nightmares.

While the Jeep 3.8L engine has powered countless wilderness expeditions, it’s developed quite a reputation for mechanical gremlins that can leave you stranded – and your wallet empty. From mysterious oil disappearances to frustrating power losses, these issues have left many Jeep enthusiasts scratching. Before you commit to this legendary power plant, let’s explore the 10 most common problems that plague the 3.8L engine and what they could mean for your off-road aspirations.

Oil Consumption Issues

Symptoms of Excessive Oil Burning

-

Blue-gray exhaust smoke, especially during acceleration

-

Oil levels drop significantly between changes

-

Strong burning oil smell while driving

-

Oil spots under the vehicle after parking

-

Engine running rough or misfiring

Common Causes and Contributing Factors

The Jeep 3.8L engine is notorious for oil consumption issues, typically consuming 1 quart every 1,000-2,000 miles. Here’s what contributes to this problem:

| Contributing Factor | Impact Level | Common in Model Years |

|---|---|---|

| Worn piston rings | High | 2007-2009 |

| Valve seal deterioration | Medium | All years |

| PCV system malfunction | Medium | 2008-2011 |

| Oil quality issues | Low | All years |

Impact on Engine Performance

Excessive oil consumption in the Jeep 3.8 engine directly affects performance in several ways:

-

Reduced engine power due to oil-fouled spark plugs

-

Increased engine temperature from inadequate lubrication

-

Carbon buildup on valves and pistons

-

Potential catalytic converter damage

-

Accelerated wear on internal engine components

Regular monitoring becomes crucial, with owners needing to check oil levels every 500 miles. While some consumption is considered normal by Chrysler’s standards, excessive burning can lead to premature engine wear. Modern synthetic oils can help minimize these issues but don’t completely resolve the underlying design flaws.

Now, let’s examine another critical issue accompanying oil consumption: cylinder head problems.

Cylinder Head Problems

Cracking and Warping Signs

-

Visible cracks on the cylinder head surface

-

White exhaust smoke

-

Coolant mixing with oil

-

Decreased engine performance

-

Rough idling and misfires

Overheating Relationship

Cylinder head issues in the Jeep 3.8L engine are often directly linked to overheating. When engine temperatures exceed normal operating ranges, the aluminum head material can warp, leading to gasket failure and eventual cracking.

| Temperature Range | Risk Level | Potential Damage |

|---|---|---|

| Below 220°F | Safe | Minimal risk |

| 220-230°F | Warning | Potential warping |

| Above 230°F | Critical | Severe damage risk |

Prevention Methods

-

Regular coolant maintenance

-

Installing an upgraded cooling system

-

Monitoring temperature gauge

-

Avoiding prolonged idle periods

-

Using high-quality head gaskets

-

Following proper break-in procedures

Repair Costs

The financial impact of cylinder head repairs can be significant:

| Repair Type | Cost Range |

|---|---|

| Head Gasket | $1,200-1,800 |

| Head Replacement | $2,500-3,500 |

| Complete Rebuild | $3,500-4,500 |

Cylinder head problems in the Jeep 3.8 engine often manifest gradually, making early detection crucial. Regular inspection of coolant levels and oil conditions can help identify potential issues before they become severe. When maintaining your Jeep’s engine, pay special attention to cooling system components, which are vital in preventing head-related failures. Next, we’ll explore how manifold failures can compound these cylinder head issues.

Manifold Failures

Exhaust Manifold Cracks

The Jeep 3.8L engine commonly experiences exhaust manifold cracks, particularly around the third and fourth cylinders. These cracks typically develop due to:

-

Repeated heating and cooling cycles

-

Off-road stress and vibration

-

Poor factory design tolerances

-

Age-related metal fatigue

Intake Manifold Gasket Leaks

Intake manifold gasket failures are another significant concern, presenting through:

-

Coolant leakage

-

Vacuum leaks

-

Rough idle performance

-

Decreased fuel efficiency

Performance Impact

Manifold issues severely affect engine performance in several ways:

| Impact Area | Symptoms |

|---|---|

| Power Output | 15-25% reduction in horsepower |

| Fuel Economy | Up to 20% decreased efficiency |

| Emissions | Failed emissions tests |

| Engine Health | Increased wear on other components |

Early warning signs include:

-

Distinctive ticking noise, especially when cold

-

Exhaust leaks under the vehicle

-

Sweet coolant smell from the engine bay

-

Check Engine Light activation

Depending on the specific failure, professional repair costs typically range from $500 to $1,200. DIY repairs are possible but challenging due to the tight spaces and specialized tools required. Preventive measures include regular inspection and avoiding extreme temperature changes.

Now that we’ve covered manifold issues let’s examine another critical problem area: timing chain complications. If left unchecked, these can lead to even more severe engine damage.

Timing Chain Complications

Early Wear Patterns

The Jeep 3.8L engine’s timing chain system often shows premature wear, typically between 70,000 and 90,000 miles. This is significantly earlier than the expected 120,000-mile industry standard.

Warning Signs

-

Rattling noise during cold starts

-

Metal shavings in oil during changes

-

Check engine light with timing-related codes

-

Rough idling or engine misfires

-

Decreased engine performance

Replacement Intervals

| Mileage | Recommendation | Risk Level |

|---|---|---|

| 0-60k | Inspection | Low |

| 60-80k | Close monitoring | Moderate |

| 80k+ | Replacement | High |

Cost Implications

The complete timing chain replacement package typically costs:

-

Parts: $400-$600

-

Labor: $800-$1,200

-

Total: $1,200-$1,800

Prevention Tips

-

Regular oil changes every 3,000-5,000 miles

-

Use high-quality synthetic oil

-

Address unusual noises immediately

-

Perform regular timing chain tension checks

-

Keep detailed maintenance records

The timing chain system’s reliability directly impacts the engine’s cooling efficiency. A worn timing chain can affect valve timing, leading to irregular engine temperatures.

Now, let’s examine how these timing issues can contribute to various cooling system problems in the 3.8L engine.

Cooling System Deficiencies

Common Failure Points

The Jeep 3.8L engine’s cooling system exhibits several critical weak points that owners frequently encounter:

-

Thermostat housing cracks

-

Water pump premature failure

-

Radiator plastic tank separation

-

Coolant reservoir leaks

-

Head gasket deterioration

Temperature Management Issues

Temperature regulation in the 3.8L engine presents significant challenges, particularly during demanding conditions:

| Condition | Impact | Warning Signs |

|---|---|---|

| Highway Driving | Moderate to High | Temperature gauge fluctuation |

| Off-Road Use | Severe | Frequent overheating |

| City Traffic | Mild to Moderate | Inconsistent cooling |

| Towing | High | Rapid temperature spikes |

Impact on Engine Life

Poor cooling system performance significantly affects engine longevity. When the cooling system fails to maintain proper operating temperatures, it accelerates wear on crucial components, particularly the cylinder heads and gaskets. Regular monitoring becomes essential, as temperature spikes can lead to:

-

Warped cylinder heads

-

Compromised head gaskets

-

Increased oil consumption

-

Reduced engine performance

-

Potential catastrophic failure

These cooling system deficiencies often manifest between 60,000 and 80,000 miles, making preventative maintenance crucial. Installation of an aftermarket temperature gauge can help monitor engine health more accurately than the stock unit.

Now, let’s examine another serious concern that often accompanies cooling system problems – engine knocking, which can indicate severe internal damage.

Engine Knocking

Root Causes

Engine knocking in the Jeep 3.8 engine typically stems from several critical issues:

-

Carbon deposits in combustion chambers

-

Degraded fuel injectors

-

Worn rod bearings

-

Incorrect spark plug gap

-

Low-quality fuel usage

Diagnostic Approaches

| Symptom | Possible Cause | Initial Check |

|---|---|---|

| Low-pitch knock | Rod bearing wear | Oil pressure test |

| High-pitch ping | Carbon buildup | Fuel quality check |

| Intermittent knock | Fuel injector issues | Injector spray pattern |

| Cold-start knock | Timing chain wear | Timing chain inspection |

Solutions and Fixes

The most effective solutions for Jeep 3.8 engine knocking include:

-

Regular Maintenance:

-

Use high-quality 87-octane fuel minimum

-

Change oil every 5,000 miles

-

Replace spark plugs at recommended intervals

-

-

Professional Repairs:

-

Fuel system cleaning

-

Rod bearing replacement

-

Injector service or replacement

-

For severe cases, the repair costs can range from $500 for minor fixes to $3,000 for major repairs. Always address knocking immediately to prevent catastrophic engine failure.

The cooling system prevents engine knock, as excessive heat can worsen these issues. Let’s examine how cooling system deficiencies can further impact your Jeep’s performance.

Valve Train Issues

Rocker Arm Problems

The Jeep 3.8L engine frequently experiences rocker arm wear and failure, particularly after 80,000 miles. Common symptoms include:

-

Ticking sounds from the valve cover

-

Reduced engine performance

-

Increased oil consumption

-

Rough idling

Valve Spring Failures

Valve springs in the 3.8L engine are known to weaken over time, leading to:

-

Valve float at higher RPMs

-

Inconsistent valve timing

-

Potential valve-to-piston contact

Performance Effects

Valve train issues significantly impact engine performance:

| Symptom | Impact Level | Common Occurrence |

|---|---|---|

| Power Loss | Severe | 60-80k miles |

| Misfires | Moderate | 70-90k miles |

| Rough Idle | Mild to Severe | 50-70k miles |

Maintenance Requirements

Regular maintenance is crucial to prevent valve train failure:

-

Oil changes every 3,000-5,000 miles

-

Valve adjustment checks every 30,000 miles

-

Regular valve cover gasket inspection

-

Use of high-quality oil with proper viscosity

The severity of these valve train issues often leads owners to consider extensive repairs or engine replacement. However, proper maintenance can prevent or at least delay many problems. As we examine power output concerns next, it’s important to note how valve train problems directly contribute to decreased engine performance.

Electronic Control Issues

Sensor Failures

-

Oxygen (O2) sensor malfunctions causing poor fuel economy

-

Mass Airflow Sensor (MAF) issues leading to rough idling

-

Crankshaft Position Sensor failures cause unexpected stalling

-

Temperature sensor inaccuracies affecting engine performance

Computer Glitches

-

PCM (Powertrain Control Module) programming errors

-

Erratic idle control system behavior

-

False check engine light warnings

-

Transmission control module communication failures

Diagnostic Solutions

| Issue Type | Common Symptoms | Recommended Fix | Approximate Cost |

|---|---|---|---|

| O2 Sensor | Poor MPG, Rough Idle | Sensor Replacement | $150-300 |

| MAF Sensor | Stalling, Hard Starts | Cleaning/Replacement | $80-400 |

| PCM Issues | Multiple Warning Lights | Reprogramming | $200-500 |

The Jeep 3.8’s electronic control system frequently experiences sensor-related problems that can significantly impact engine performance. The oxygen sensor usually deteriorates prematurely, leading to poor fuel mixture and reduced efficiency. The Mass Airflow Sensor often becomes contaminated, causing erratic engine behavior and starting difficulties.

These issues are compounded by the PCM’s tendency to develop glitches, especially in 2007-2011 models. Regular diagnostic scanning using professional-grade tools is essential for early problem detection. Many owners succeed with aftermarket sensors, which often prove more reliable than OEM parts.

Cooling system problems are closely related to electronic control issues, so maintaining proper engine temperature is crucial for preventing sensor failures.

Power Output Concerns

Performance Limitations

The Jeep 3.8L engine’s modest 202 horsepower output often falls short of expectations, especially compared to modern counterparts. This limitation becomes particularly noticeable during:

-

Highway passing maneuvers

-

Steep incline climbing

-

Heavy cargo hauling

-

High-altitude driving conditions

Torque Problems

While the engine produces 237 lb-ft of torque, real-world performance shows several weaknesses:

-

Delayed throttle response

-

Inconsistent power delivery

-

Struggling performance under load

-

Limited towing capacity

Fuel Efficiency Impact

The 3.8L engine’s power deficiencies often lead to compromised fuel economy, as shown in this comparison:

| Driving Condition | Expected MPG | Actual MPG | Efficiency Loss |

|---|---|---|---|

| City Driving | 17 | 15 | -12% |

| Highway Driving | 21 | 18 | -14% |

| Off-Road Use | 14 | 11 | -21% |

These power output issues often force drivers to push the engine harder, increasing fuel consumption and additional strain on engine components. Compared to the later 3.6L Pentastar engine, the 3.8L’s performance limitations become even more apparent, with the newer engine offering improved power delivery and fuel efficiency.

The underwhelming power output and poor fuel economy make this engine particularly challenging for owners who regularly use Jeeps for towing or aggressive off-road activities. Now, let’s examine how these various issues contribute to the overall reliability assessment of the 3.8L engine.

Overall Reliability Assessment

Common Maintenance Requirements

-

Oil changes every 3,000-5,000 miles

-

Regular cooling system flushes

-

Frequent spark plug replacements

-

Timing chain inspection every 60,000 miles

-

Valve cover gasket replacement as needed

Long-term Durability Factors

The 3.8L engine typically lasts 150,000-200,000 miles with proper maintenance, though several factors affect its longevity:

| Factor | Impact on Durability |

|---|---|

| Oil Consumption | High consumption rates reduce engine life |

| Heat Management | Poor cooling leads to premature wear |

| Driving Conditions | Off-road use accelerates wear |

| Maintenance History | Regular service extends the lifespan |

Cost of Ownership

The average annual maintenance costs range from $800-$1,500, with major repairs potentially adding:

-

Cylinder head replacement: $2,000-$3,000

-

Timing chain repair: $1,200-$1,800

-

Manifold replacement: $500-$900

Alternatives to Consider

When comparing reliability, the newer 3.6L Pentastar engine offers significant improvements:

-

Better fuel efficiency

-

More reliable oil consumption

-

Improved power output

-

Lower maintenance costs

-

Better overall durability

While the Jeep 3.8 engine has a decent service life, it requires more attention and maintenance than modern alternatives. The 3.6L Pentastar engine presents a more reliable option for those considering a Jeep Wrangler purchase. With increasing repair costs and potential issues as these engines age, carefully considering upgrade options becomes increasingly important.

While powering many memorable off-road adventures, the Jeep 3.8L engine comes with significant challenges that potential buyers should carefully consider. From excessive oil consumption to persistent cooling system problems, these issues can impact performance and long-term reliability. Combined cylinder head defects, manifold failures, and timing chain complications often lead to costly repairs and maintenance requirements.

Before investing in a vehicle equipped with a 3.8L engine, thoroughly inspect its maintenance history and consider having a professional mechanic evaluate its condition. While these engines can provide reliable service when properly maintained, the numerous potential problems may make alternative engine options more appealing for those seeking a dependable off-road companion. Regular maintenance, proactive repairs, and careful attention to warning signs will be crucial for anyone proceeding with this engine.

Jack Thompson is a writer and seasoned auto mechanic with over 15 years of experience in the automotive industry. Known for his expertise in vehicle mechanics, Jack has a deep understanding of car and truck systems. His skills, honed through years of hands-on experience, have made him a trusted name in the field. Jack is committed to providing valuable insights into car maintenance and repair, helping vehicle owners keep their vehicles in top condition.