Imagine the frustration of a car owner who replaced their camshaft position sensor but still faces engine issues. The check engine light is a constant reminder of the problem. This shows how tricky it can be to fix camshaft position sensor problems, even after a replacement.

We’ll explore the camshaft position sensor’s role in the engine and common symptoms of a faulty sensor. We’ll also guide you on how to troubleshoot, including reading error codes and using a multimeter.

Understanding the key components and factors that lead to camshaft position sensor issues can help. This knowledge empowers car owners to fix their vehicle’s performance problems.

Key Takeaways

- Replacing the camshaft position sensor may not always resolve the underlying issue, leading to persistent error codes and engine problems.

- Proper diagnosis, including reading error codes and conducting multimeter tests, is crucial in identifying the root cause of the problem.

- Compatibility issues with aftermarket replacement sensors can contribute to ongoing issues, emphasizing the importance of using the correct OEM parts.

- Addressing any related component failures, such as the crankshaft position sensor or timing belt/chain, is essential for a comprehensive resolution.

- Environmental factors, such as oil leaks and high engine temperatures, can impact the camshaft position sensor’s performance and contribute to the problem.

Understanding the Camshaft Position Sensor

The camshaft position sensor is key to your car’s engine performance. It helps with engine timing issues and ignition system problems. This sensor sends important info to the Powertrain Control Module (PCM). This info helps the PCM time ignition sparks and fuel injections perfectly.

What is a Camshaft Position Sensor?

This sensor is an electronic part that watches the camshaft’s position and speed. It sends signals to the PCM. The PCM then uses this data to make sure the engine’s ignition and fuel systems work together well. This improves the engine’s performance.

How It Works in Your Engine

When the camshaft moves, the sensor catches its position and speed. It sends this info to the PCM. The PCM then times the ignition sparks and fuel injections right. If the sensor doesn’t work right, it can cause problems like misfires, stalls, and a check engine light.

“The camshaft position sensor is a critical component in your vehicle’s engine management system, responsible for maintaining proper engine timing and fuel delivery.”

Common Symptoms of a Faulty Camshaft Position Sensor

When your vehicle’s camshaft position sensor goes wrong, you’ll notice several issues. The first sign is usually the check engine light turning on. This light warns you of a problem that needs fixing right away. If you ignore it, you might face bigger engine or transmission problems later.

Engine Misfires and Stalling

A bad camshaft position sensor can make your engine misfire or stall. It sends important info to the engine control module (ECM) about the camshaft’s position and timing. If this info is off, your engine might not run well. You might see it sputter, lose power, or even shut off while driving.

Check Engine Light Activation

The check engine light is a clear sign of a failing camshaft position sensor. It turns on when the ECM spots a problem with the sensor. This could be due to wiring issues, sensor problems, or issues with the sensor and camshaft. Don’t ignore the check engine light, as it can cause more damage. It’s vital to get it checked and fixed quickly.

Fixing a faulty camshaft position sensor is key to keeping your vehicle running right. Knowing the common symptoms helps you catch and fix the problem early. This way, you avoid expensive repairs later on.

Potential Causes for Persistent Error Codes

Replacing the camshaft position sensor is a common fix, but it’s not always enough. Error codes can keep coming back due to many reasons. These include wrong sensor installation, faulty wiring, or problems with aftermarket parts.

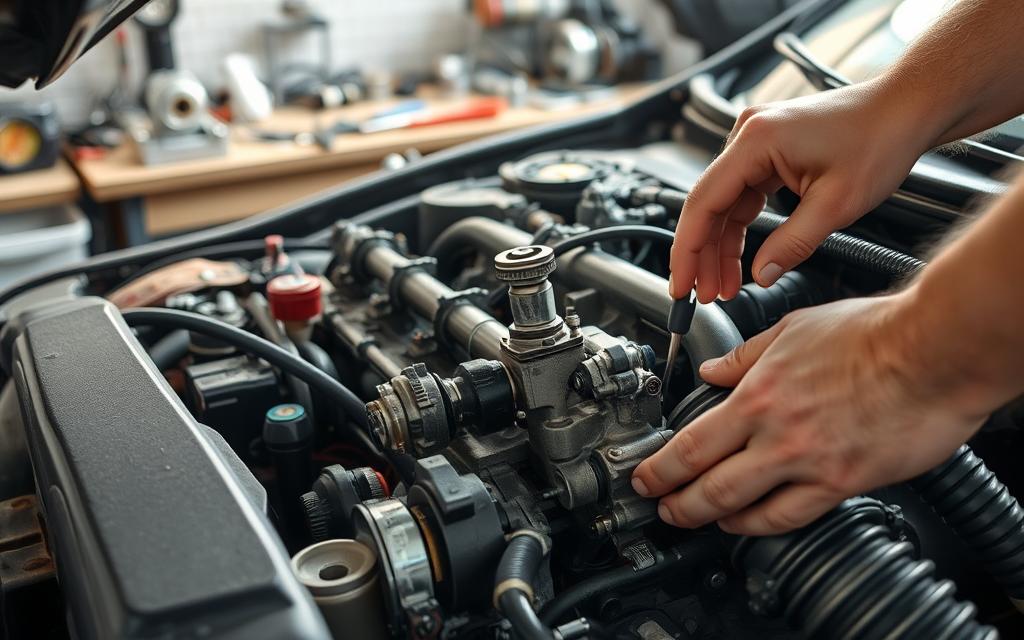

Incorrect Installation of the New Sensor

Installing the new camshaft position sensor wrong can cause error codes to stay. Make sure the sensor is well-mounted and the connectors are tight. Also, check that the sensor is correctly aligned with the camshaft. If not, the sensor can’t read the camshaft’s position right, leading to more error codes.

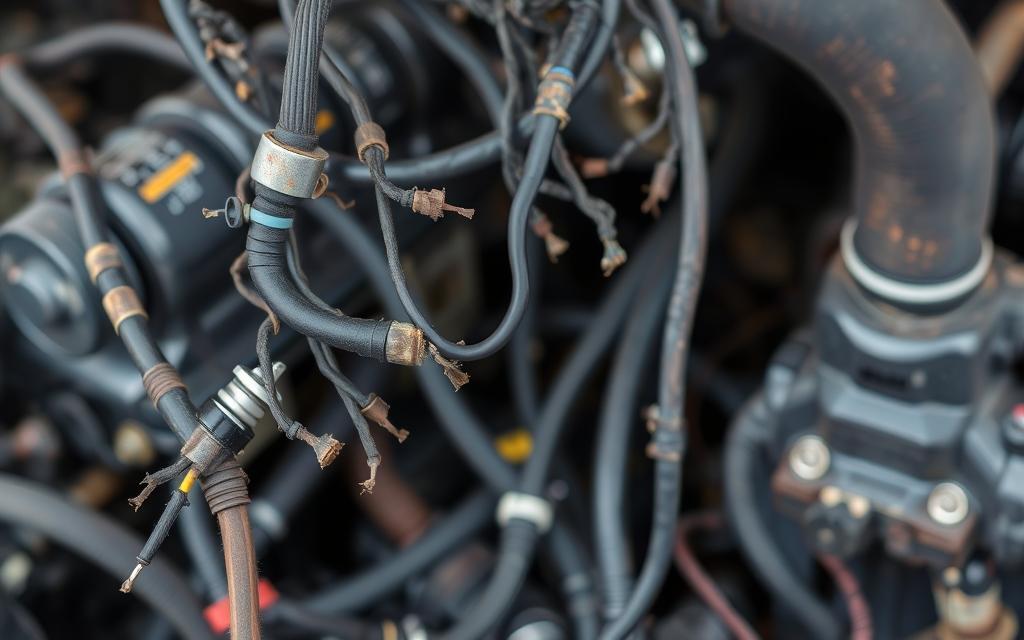

Faulty Wiring or Connectors

The camshaft position sensor needs a wiring harness to talk to the engine control unit (ECU). Any wiring problems, like damage or loose connections, can mess up the sensor’s signal. This can lead to error codes that won’t go away. Look over the wiring and connectors for any damage and fix any issues you find.

Sometimes, the issue might be with the wiring harness or needing to ECU reprogram to work with the new sensor. It’s key to do the right diagnostic steps to find the real cause of the error codes.

“I replaced the cam sensor, but the code came back after a week. Turns out, the wiring harness was damaged near an idler pulley, causing an intermittent short. Once the wiring was fixed, the check engine light went away and hasn’t come back since.”

By tackling these possible causes, you can fix the persistent error codes. This ensures your vehicle’s camshaft position sensor works as it should.

Diagnosing the Issue

To fix the error codes after replacing the camshaft position sensor, you need a careful plan. Start by reading the diagnostic trouble codes. Then, use tools like multimeters to check the sensor and wiring.

Reading the Error Codes

The first thing to do is read the error code, like P0340. This code means there’s a problem with the camshaft position sensor circuit. Knowing the code helps you find the problem and fix it.

Using a Multimeter for Testing

A multimeter is key for checking the camshaft position sensor system’s electrical parts. It lets you test the sensor’s voltage, resistance, and continuity. You can also check the wiring for any problems. This testing helps figure out if the new sensor works or if there are other issues.

| Test | Expected Values |

|---|---|

| Voltage | 5V DC |

| Resistance | Between 800-2,000 ohms |

| Continuity | Continuous path between sensor and ECU |

By carefully checking the error codes and using a multimeter, you can find the problem. Then, you can fix it right.

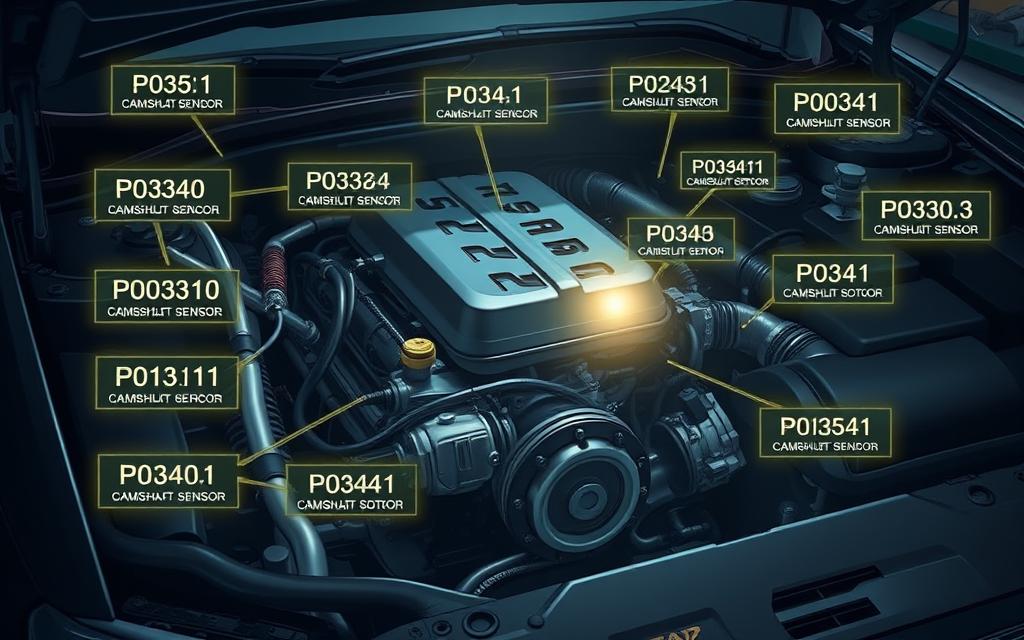

Common Error Codes Associated with Camshaft Position Sensors

When a camshaft position sensor (CPS) goes wrong, it can set off trouble codes. These codes give us clues about what’s wrong. Two common ones are P0340 and P0341.

P0340: Camshaft Position Sensor Circuit

The P0340 code means there’s a problem with the CPS circuit. This could be due to a wiring fault, a bad sensor, or an issue with the engine control module (ECM). If you see this code, it might cause engine misfires, stalling, and poor performance.

P0341: Camshaft Position Sensor Range/Performance

The P0341 code tells us the CPS isn’t sending the right signal. This could be because the sensor is misaligned, worn out, or has mechanical problems. Like P0340, it can lead to engine troubles and lower fuel efficiency.

Replacing a faulty CPS might not fix these codes if other engine parts are also at fault. It’s crucial to find and fix the real problem for a lasting solution.

| Error Code | Description | Potential Causes |

|---|---|---|

| P0340 | Camshaft Position Sensor Circuit Malfunction | Wiring issues, faulty sensor, ECM problems |

| P0341 | Camshaft Position Sensor Range/Performance | Sensor misalignment, mechanical issues, wear and tear |

Compatibility Issues with Replacement Sensors

Choosing between OEM and aftermarket camshaft position sensors is crucial for fixing ignition system problems. OEM parts are often more reliable and compatible than aftermarket ones. This is because OEM parts are made for your specific vehicle, ensuring a perfect fit.

OEM vs. Aftermarket Parts

Going for an OEM camshaft position sensor is usually the best choice. These sensors are made for your vehicle, guaranteeing a smooth connection with the ignition system. On the other hand, some aftermarket parts may not work well, leading to ongoing issues.

| OEM Camshaft Position Sensors | Aftermarket Camshaft Position Sensors |

|---|---|

| Designed and manufactured for your vehicle | May not fit or work with your engine |

| Consistent and reliable performance | Quality issues or compatibility problems |

| Warranty from the vehicle manufacturer | No or limited warranty |

While OEM sensors cost more upfront, their reliability and long-term performance are worth it. Thinking about the risks and benefits can help you choose the right sensor. This ensures a successful replacement and fixes ignition system problems.

Other Components to Inspect After Replacement

When dealing with a malfunctioning camshaft position sensor, it’s crucial to check other engine parts. You should look at the crankshaft position sensor and the timing belt or chain’s condition.

Crankshaft Position Sensor

The crankshaft position sensor works with the camshaft sensor to give the engine control module (ECM) timing info. A faulty crankshaft sensor can cause engine misfires, stalls, and a Check Engine Light. Testing this sensor can reveal underlying problems.

Timing Belt or Chain Condition

The timing system, with its belt or chain, is vital for the engine’s smooth operation. A damaged timing part can make the camshaft and crankshaft desynchronize. This can lead to issues like error codes related to the camshaft sensor. Inspecting the timing belt or chain for wear signs is important.

Checking these related components helps find the problem’s source. This ensures a successful fix for the camshaft position sensor’s error codes.

Environmental Factors Affecting Sensor Performance

In the automotive world, sensors like the camshaft position sensor face challenges. Oil leaks and contaminants, along with high engine temperatures, play a big role. These factors can greatly affect how well the sensor works.

Oil Leaks and Contaminants

Oil leaks and contaminants can mess with the sensor’s job. They make it hard for the sensor to accurately measure camshaft position. This can lead to engine misfiring and other ignition system problems.

Regular maintenance and quick action on oil leaks are key. They help keep the sensor working right.

High Temperatures in the Engine Compartment

The engine compartment is tough on sensors like the camshaft position sensor. High temperatures can damage the sensor over time. This can cause engine misfiring and other issues.

It’s important to use heat shielding and good ventilation. This helps prevent the sensor from failing too soon.

Knowing how environmental factors affect sensors helps owners and technicians. They can take steps to avoid error codes and engine problems. This is all about keeping the camshaft position sensor working well.

“Consistent maintenance and vigilance in monitoring the engine environment are key to ensuring the longevity and reliable performance of critical sensors like the camshaft position sensor.”

Importance of Proper Maintenance

Keeping your car’s engine parts, like the camshaft position sensor, in good shape is key. Regular checks and clean engine parts can stop problems before they start. This keeps your car running smoothly.

Regular Diagnostic Scans

Scanning your car’s computer often can spot issues early. This includes problems with the camshaft position sensor or other parts. Fixing these issues quickly can save you from expensive repairs later.

Keeping Engine Components Clean

A clean engine is vital for the camshaft position sensor to work right. Dirt and oil can mess with the sensor, causing it to send out wrong signals. Cleaning your engine regularly helps your sensor last longer and avoids future problems.

| Maintenance Action | Benefit |

|---|---|

| Regular Diagnostic Scans | Early detection of sensor-related issues |

| Keeping Engine Components Clean | Prevents sensor malfunction and extends lifespan |

Being proactive with maintenance helps tackle check engine light and engine timing issues early. Regular scans and careful engine cleaning are crucial. They ensure your camshaft position sensor works well.

When to Seek Professional Help

When you’re trying to fix a camshaft position sensor, there’s a point where DIY won’t cut it. If you’ve tried everything and still see diagnostic trouble codes or engine misfiring, it’s time to get help from a pro.

Signs You Should Consult a Mechanic

- The check engine light stays on even after replacing the sensor

- The engine keeps misfiring or stalling without reason

- You can’t clear the diagnostic trouble codes

- You think there might be problems with other parts too

The Benefits of Expert Diagnosis

A certified mechanic has the tools and software to really dig into your car’s issues. They can find out what’s wrong, like a wiring problem or a sensor that doesn’t fit right. Their skills can save you time, money, and a lot of frustration.

“Don’t hesitate to seek professional help if you’ve exhausted your own troubleshooting efforts. A qualified mechanic can often identify and resolve issues that may not be apparent to the average vehicle owner.”

Getting a mechanic involved means your car will get fixed right. They know what they’re doing and can make sure your car runs well again. Their experience is priceless in getting your car back on the road.

Cost Considerations for Troubleshooting

Fixing a camshaft position sensor that keeps causing problems can cost a lot. While fixing it yourself might save money, it might not solve the issue. Often, you need more detailed checks to find the real problem.

Typical Costs for Sensor Replacement

Replacing a camshaft position sensor can cost between $50 and $150. This depends on your car’s make and model. Labor costs can add another $50 to $100. Using a part made by the car’s manufacturer might cost more but ensures it fits right.

Additional Costs for Diagnostic Services

If the sensor swap doesn’t fix the trouble codes, you might need more tests. A basic check can cost between $94.99 and $114.99. More detailed checks can cost even more.

Some problems might mean bigger issues like engine or electrical system problems. This could lead to more expensive repairs or even replacing parts. These extra costs can add up fast.

When dealing with a camshaft position sensor that keeps causing trouble, think about the costs. Planning and budgeting can help you make smart choices. This way, you can avoid spending too much on fixing your car.

Owner Experiences: Troubleshooting Tips

Many car owners have found ways to fix error codes after replacing the camshaft position sensor. They suggest straightening bent connector prongs and making sure the new sensor is securely connected.

One owner, with a car at 147,000 miles, had trouble with an OBDI code 1244. The code showed up when the car bucked and hesitated. Even after replacing the sensor, the problem didn’t go away.

Real Stories from Vehicle Owners

Another owner, with a car at 187,000 miles, had a car shut down while driving home from church. Luckily, they could start it again and drive for five miles before it stopped again. They also noticed a problem with the blower motor and a fluctuating idle.

Yet another owner’s car had trouble starting, bucking, and hesitating, mostly in wet weather. They tried replacing the fuel filter and spark plugs but still had issues with misfires and poor performance.

Sharing Best Practices

- Use Original Equipment Manufacturer (OEM) parts for the camshaft position sensor to avoid compatibility problems.

- Check the crankshaft position sensor and the condition of the timing belt or chain, as they can also cause issues.

- Look for carbon buildup on the sensor, as one owner found it covering about 60% of the tip.

- Test the sensor’s resistance to see if it needs to be replaced, as one owner found readings of 0.666 at 2M ohms and 92.3 at 200K ohms.

By sharing their experiences and tips, car owners can help others deal with replaced camshaft position sensor but still get code and engine misfiring problems more effectively.

Conclusion: Addressing the Issue Effectively

Fixing persistent camshaft position sensor codes needs more than just a new sensor. It’s important to find out why the problem keeps happening. This could be due to bad wiring, loose connections, or issues with aftermarket parts.

Summary of Key Takeaways

This guide has stressed the need for accurate diagnosis and using genuine parts. It’s also key to check the condition of other parts like the crankshaft sensor and timing belt. Keeping an eye on diagnostic trouble codes and a clean engine can also stop future problems.

Final Recommendations for Vehicle Owners

If you’re dealing with recurring camshaft position sensor codes, don’t just replace the sensor. You should dig deeper into the issue. This includes recording fault codes, checking connections, and getting professional advice when needed. A thorough approach will help keep your vehicle running well, even after fixing the sensor.

FAQ

Why am I still getting a code after replacing the camshaft position sensor?

What is a camshaft position sensor, and how does it work in the engine?

What are the common symptoms of a faulty camshaft position sensor?

What are some potential causes for persistent error codes after camshaft position sensor replacement?

How can I diagnose the issue with the camshaft position sensor?

What are the common error codes associated with camshaft position sensors?

How can compatibility issues affect the performance of a replacement camshaft position sensor?

What other components should I inspect after replacing the camshaft position sensor?

How can environmental factors affect the camshaft position sensor’s performance?

Why is proper maintenance important for preventing and troubleshooting camshaft position sensor-related problems?

When should I seek professional help for troubleshooting camshaft position sensor issues?

What are the typical costs involved in troubleshooting and repairing camshaft position sensor-related problems?

What are some troubleshooting tips from vehicle owners who have experienced similar issues?

Jack Thompson is a writer and seasoned auto mechanic with over 15 years of experience in the automotive industry. Known for his expertise in vehicle mechanics, Jack has a deep understanding of car and truck systems. His skills, honed through years of hands-on experience, have made him a trusted name in the field. Jack is committed to providing valuable insights into car maintenance and repair, helping vehicle owners keep their vehicles in top condition.